Purging

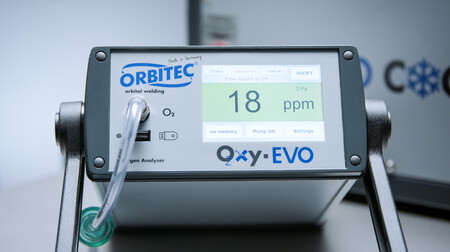

Proper purging is absolutely essential to guarantee high-quality welding of high-alloyed, corrosion-resistant components. Our Oxy EVO oxygen analyser can be connected to our orbital welding controllers for the purpose of inspecting and documenting the residual oxygen content and evaluated. You are free to choose the value in ppm entered in the controller.

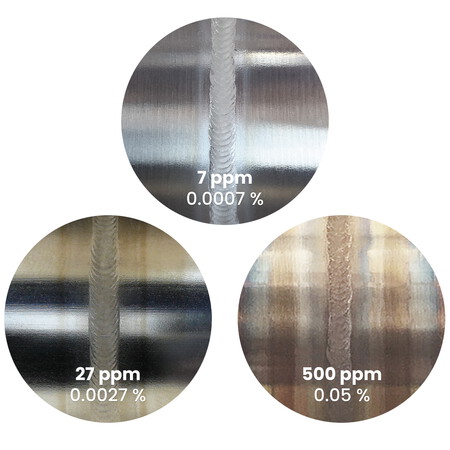

Unless specified otherwise, a value < 30 ppm is generally sufficient for starting welding. The controller will not allow welding to commence until the measured value drops below the entered value. The equipment is calibrated so that it measures with an accuracy of +/- 2 ppm in the welding-related area below 30 ppm in the case of inert gases.

Analysers that display values as percentages are not recommended ➝ 0.1% = 1,000 ppm!